Introduction

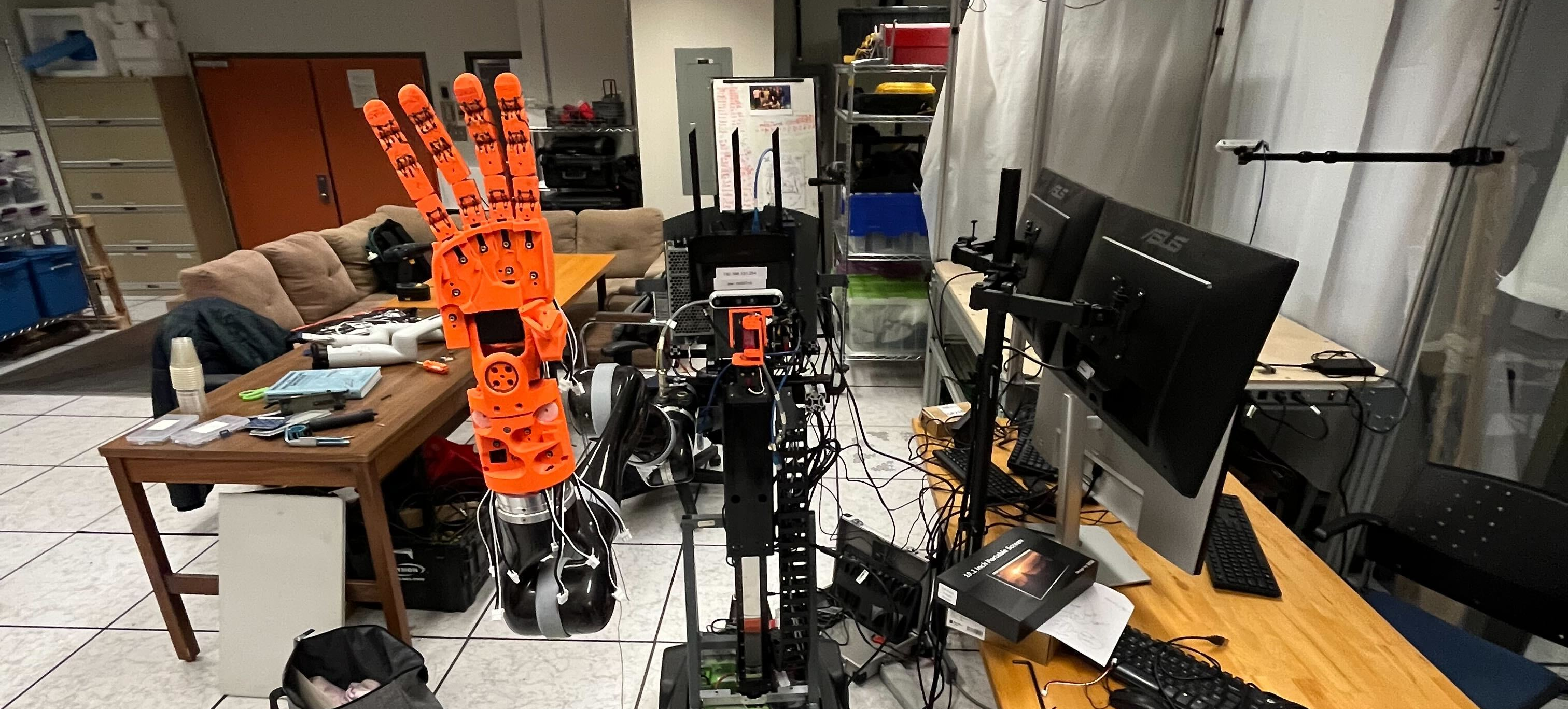

DexAloha started from a simple idea: take an open-source, low-cost hand and make it play nicely with a real robot arm.

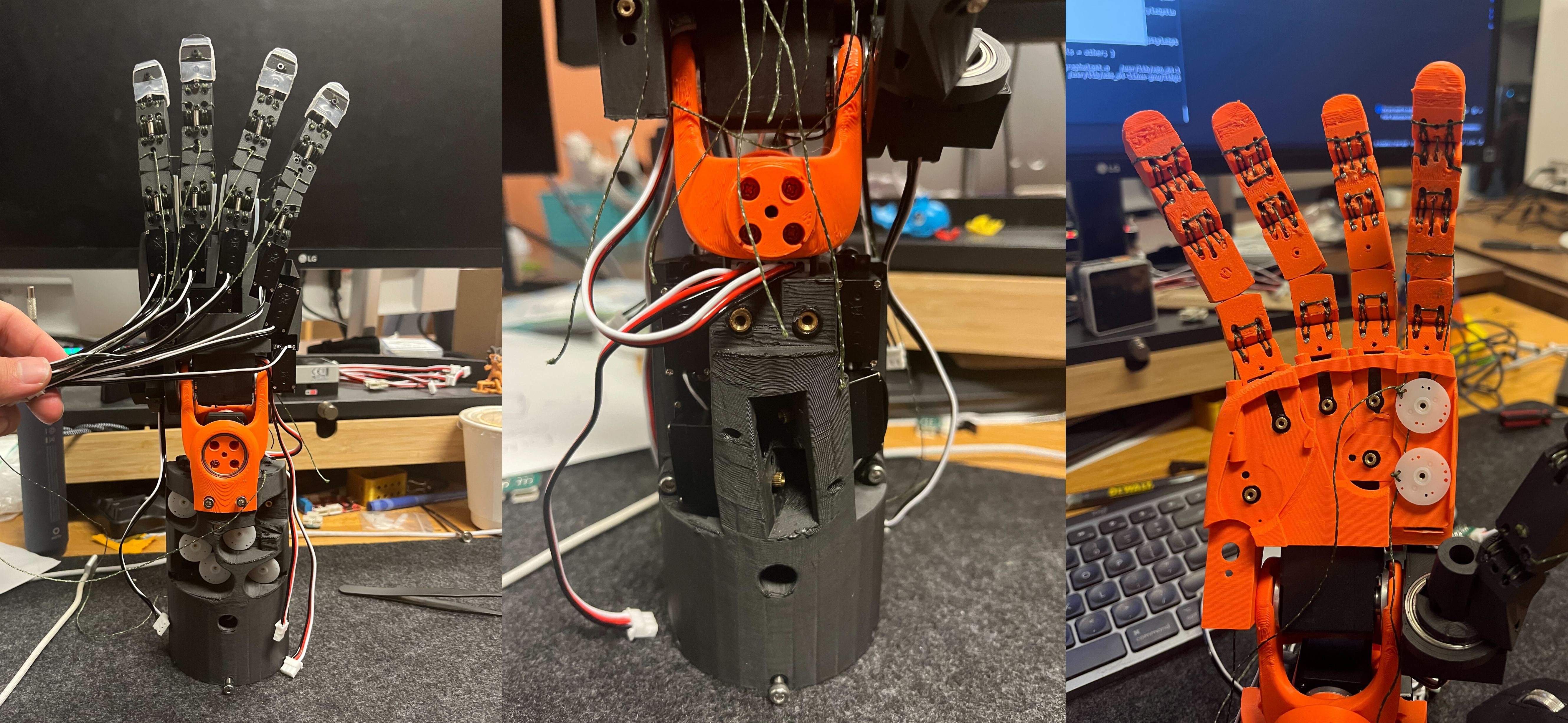

The actual core hand design is not mine – it comes from the open-source HOPE JR project. What I did here was:

- Print and assemble the HOPE JR hand,

- Design and build a custom wrist module so it bolts directly onto a Kinova Jaco,

- Tweak the cable routing,

- And, courtesy of my friend Martino Russi (Hugging Face), switch to an improved finger design that’s thicker, easier to assemble, and uses M2 screws instead of tiny fishing clamps.

So DexAloha is:

- 5 fingers, cable-driven with fishing line

- ~$300 in parts for the hand

- 18 DOF total – 3 per finger – +2 for the wrist

- Driven by FEETECH servos in a custom wrist module

- A Hall-effect glove (work in progress) for teleoperation and demos

This page walks through the main pieces: printing and assembling the HOPE JR hand, building a finger (including the new design), designing the wrist for the Jaco, wiring the FEETECH motors, and eventually constructing the glove.

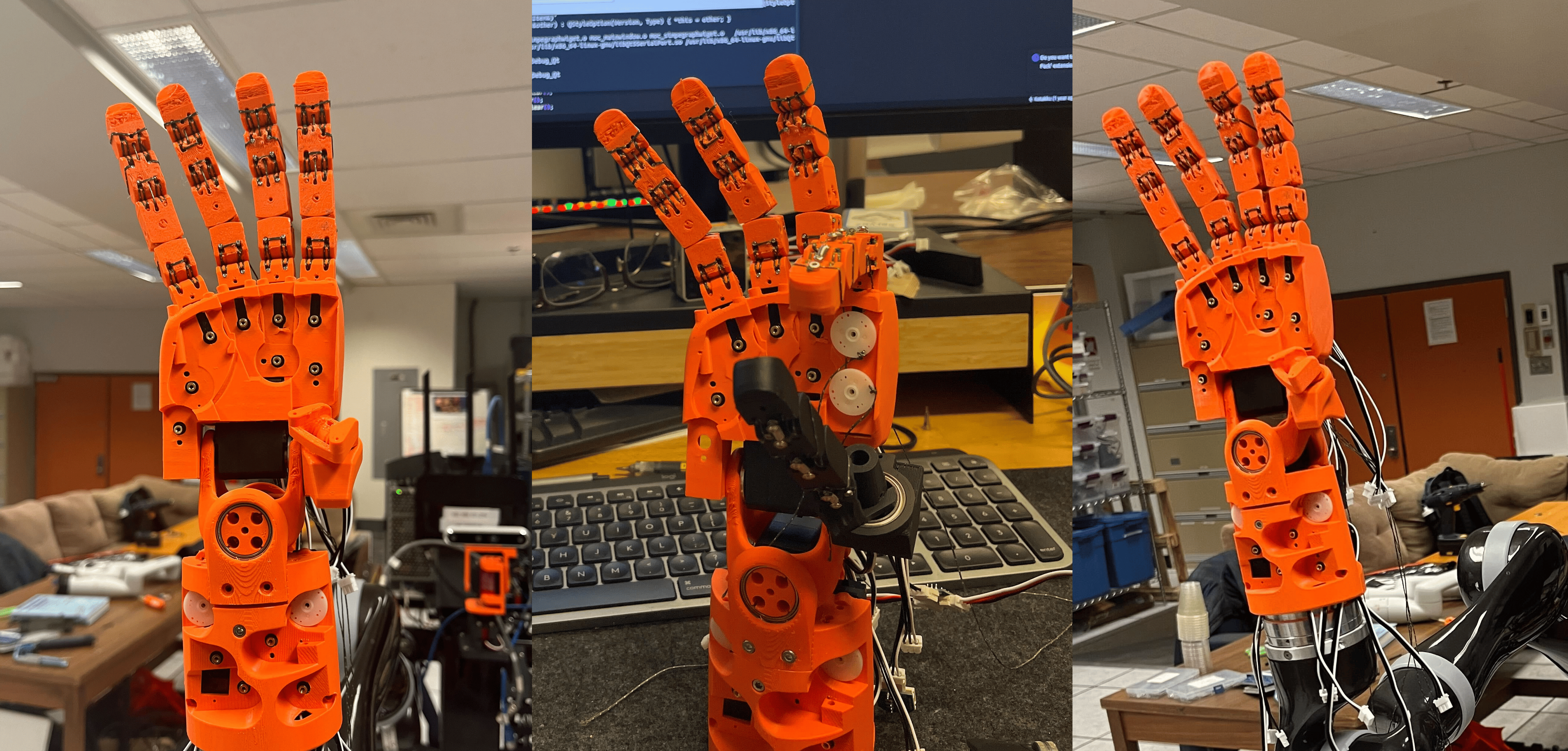

Printing & Assembling the Hand

The core geometry of DexAloha still comes from HOPE JR: finger joints, tendon paths, and overall proportions. I didn’t redesign the mechanism from scratch; I used their models as the base and focused on making them real and usable on my setup.

In practice, going from a Git repo to a physical hand still means:

- Slicing and printing all the parts,

- Cleaning up surfaces and holes,

- Test-fitting joints and tendons,

- Reprinting the parts that reality didn’t like.

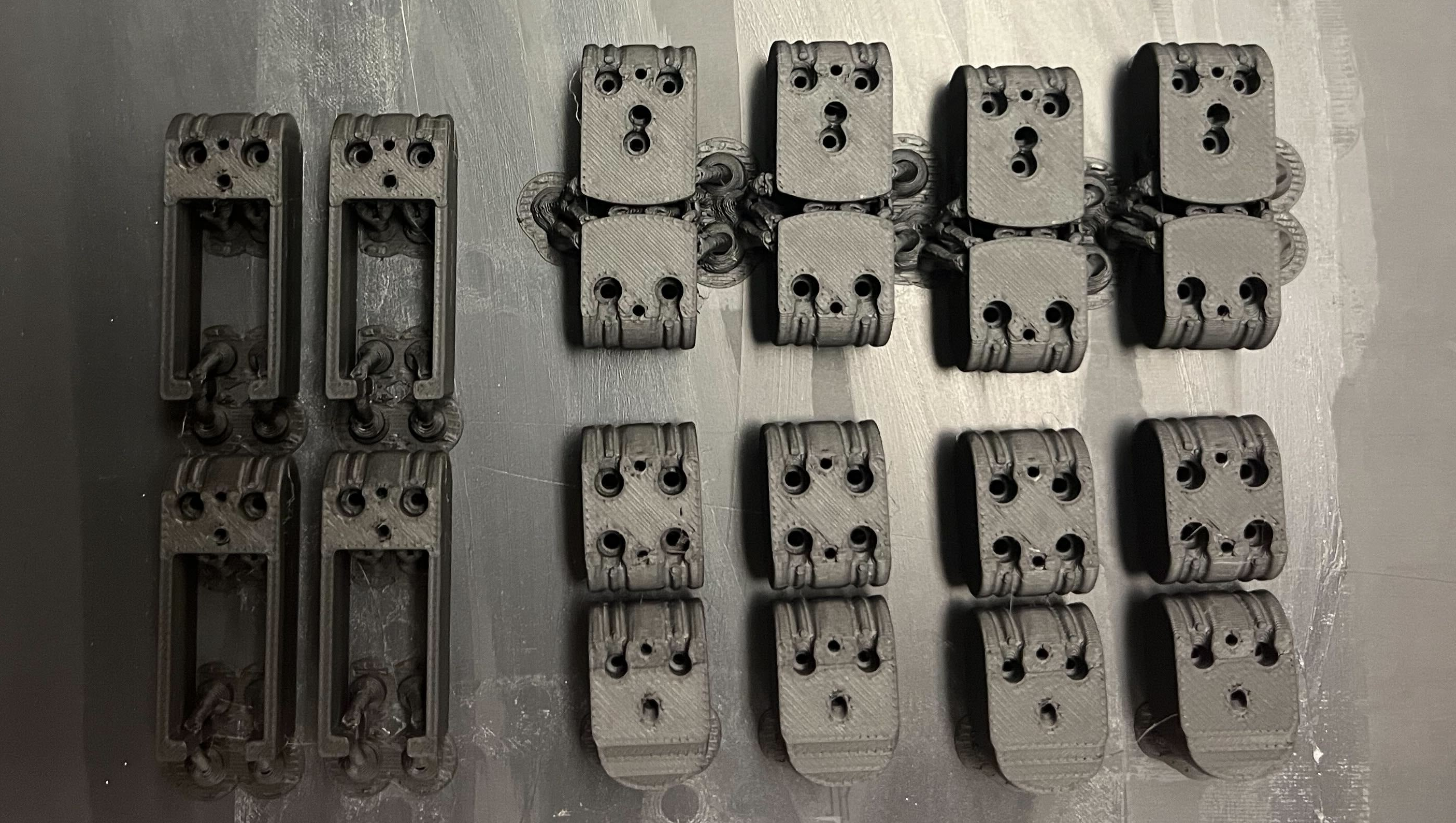

I printed the hand in multiple batches:

- Palm and backplate: the main shell that houses the cable exits and anchors.

- Five sets of finger segments: proximal, middle, distal, and fingertip parts.

- Cable guides and pulleys: tiny parts that matter a lot for friction.

Because this is cable-driven, the quality of the holes, grooves, and rounded corners is critical. Any sharp edge becomes a cable-eating device. So after printing:

- I chamfered and lightly sanded all tendon paths.

- I did a dry run with dummy fishing line to make sure the routing doesn’t snag.

Even though HOPE JR provides the base design, DexAloha still required tweaking clearances and reprinting a couple of parts until the routing felt smooth on my printer + filament + tolerances.

Assembling a Finger (and the New Design)

Each finger is its own little project. A DexAloha finger has around four pieces:

- Base segment

- Middle segment

- Distal segment

- Fingertip / cap

The original HOPE JR finger design works, but it was a bit painful to assemble: small features, tight holes, and cable terminations that were not super friendly for repeated experiments. This is where Martino Russi stepped in with a nicer variant that I ended up using:

- Thicker finger links → more robust and less flexy,

- Bigger holes → easier routing and less fighting with the fishing line,

- M2 screws for fastening → instead of relying on awkward clamps everywhere.

So the basic build flow with the new fingers is:

- Press-fit or pin/screw the joints between segments so they can rotate cleanly.

- Run fishing line through the finger along the built-in channels and enlarged holes.

- Anchor the line at the fingertip and route it back toward the palm where the servo spool sits.

We experimented with different routing patterns for the fishing line:

- Symmetric vs. offset paths around the joints,

- Single line vs. dual-line per finger,

- Different wrapping strategies around the servo horn.

The goal was to find a pattern that:

- Gives a smooth flexion curve,

- Minimizes slack and hysteresis,

- Doesn’t chew through the cable in 10 flexes.

Once a single finger behaved well (no grinding, decent range of motion), we replicated the process across all five fingers with the improved geometry.

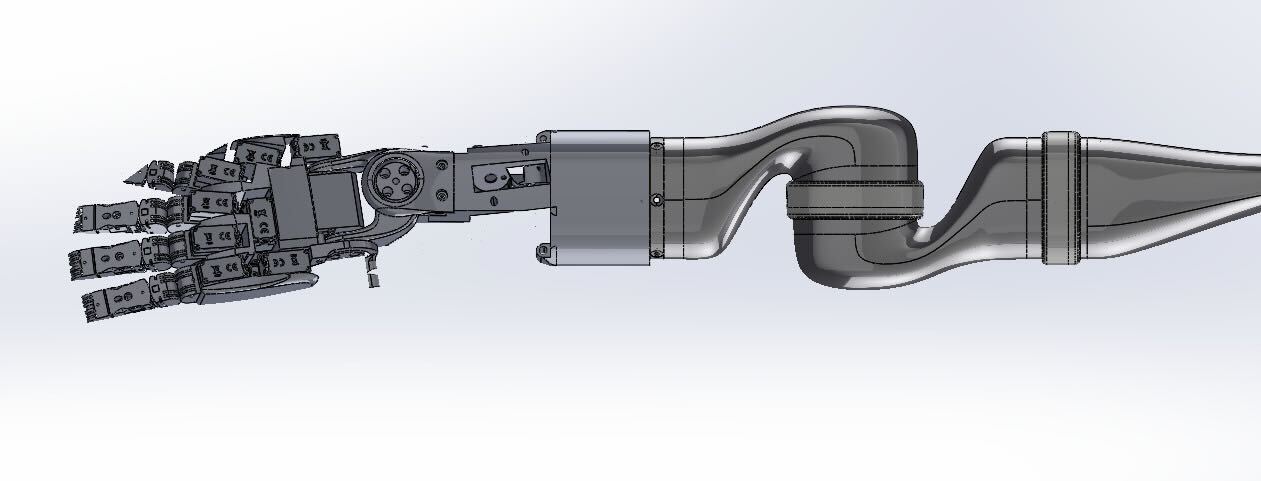

Custom Wrist for the Kinova Jaco

The original HOPE JR design doesn’t care what robot it mounts on. For DexAloha, the constraint was clear:

The whole thing needs to behave like a Jaco tool: same bolt pattern, clean wiring path, and a compact, robust wrist.

This part is custom.

We designed a wrist module that:

- On one side, interfaces mechanically with the Jaco flange (same bolt circle & alignment).

- On the other side, houses:

- A set of FEETECH servos for the fingers,

- Two larger FEETECH servos for wrist motion,

- Cable guides so the fishing lines exit cleanly into the palm.

The result:

- 18 DOF total:

- 3 DOF × 5 fingers = 15 DOF

- 2 DOF for the wrist (flexion/extension + radial/ulnar or yaw/pitch, depending on configuration)

- The wrist directly bolts into the Jaco like any other tool.

- Power and signal lines are routed through the wrist body, so there’s no spaghetti at the flange.

Where’s the learning?

If you’re wondering where the transformers, VLAs, and “actual learning” come in: DexAloha is the hardware playground for that next step. The goal is to use this underactuated, high-DOF hand as a testbed for vision–language–action policies and transformer-based controllers, how we collect data, train those models, and deploy them on the real hand will be the topic of a separate blog post.